Igranulator

Umgangatho ophezulu wemveliso yeplastiki eshushu ipellet / umbhobho / cubeextruder umatshini izixhobo zeplastiki recycling

I-SJ series ye-screw extruder yomatshini weplastiki ngokukodwa isetyenziselwa ukukhupha i-PP, i-PE, i-PET, i-PVC, i-ABS, i-PS, i-PA ect material. Yamkela ibhokisi yegiya ekhethekileyo, kwaye ineempawu zengxolo ephantsi, ukubaleka okuzinzileyo, ukuthwala okuphezulu, ubomi benkonzo ende. .Ixhotyiswe ngezixhobo ezahlukeneyo zokungunda kunye nezixhobo ezincedisayo, inokuvelisa umbhobho weplastiki, iphepha, ibhodi, iigranules njalo njalo .Ineempawu zenkqubo elula, imveliso ephezulu, uxinzelelo oluzinzileyo lwe-extrusion, kunye neendleko eziphantsi.

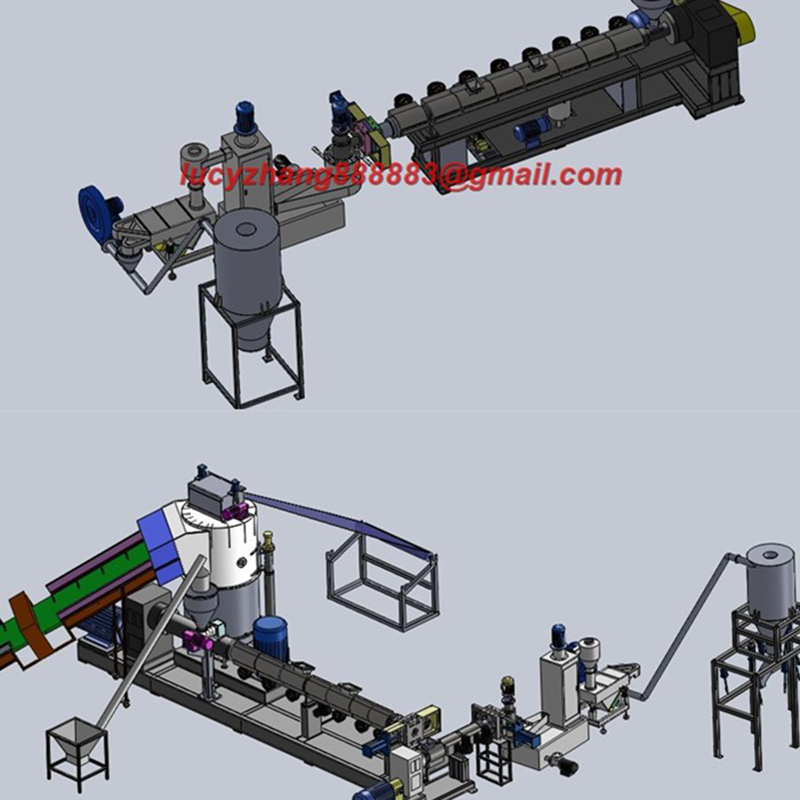

| Iprojekthi: DJ85 single screw pelletizing line |

| Imathiriyeli ekrwada & nefomula | Iifilimu ze-PE |

| Imveliso yokugqibela | PE granules |

| Umthamo wemveliso | 120-200kg/h , kuxhomekeke kwiimpawu zezinto. |

| Ukuphakama okuphakathi | 1.14m |

Umgca we-pp pelletizing umatshini weplastiki wokuphinda usebenziseke umatshini wokulahla inkunkuma yeegranule zeplastiki

Iiparamitha(CS Series Double Stage Compactor-Granulator):

| Imodeli(inqanaba eliphindwe kabini) | CS85-100 | CS100-120 | CS130-150 | CS160-180 | CS180-200 |

| Screw Diameter(mm) | 85 | 100 | 130 | 160 | 180 |

| L/D | 25-42 | 25-42 | 25-33 | 25-33 | 25-33 |

| Umthamo(kg/h) | 150-200 | 300-350 | 500 | 600-700 | 800-1000 |

Isicelo:

Ifilimu ye-PE, i-PP, i-Silk, i-Flakes (≤0.5mm), iingxowa, njl.

Qaphela, uchungechunge lwethu lwe-CS compactor granulator lunokuba yindlela yokutsala umtya, okanye indlela yokusika umsesane wamanzi ukuze ukhethe

Ine:

Ukuhambisa ibhanti(isixhobo sentsimbi) → ICompactor → I-extruder engundoqo(inkqubo yokucoca ivacuum) → Umjikijeli wesikrini osebenzisa amanzi → Umkhuseli ongaphantsi →

Umtshintshi wesikrini seHydraulic → Inkqubo yokusika ikhonkco lamanzi → Umatshini wokunkcenkceshela → Inkqubo yokuvuthela umoya → Ihopper yogcino → ulawulo lwekhabhathi

1. Iinkcukacha zajikelele

1.1Indawo yomgangatho

Ulwakhiwo olusisiseko, umsebenzi womhlaba, umsebenzi wodonga kufuneka ugqitywe kakuhle nguMthengi ngokwamkela lo mgca wepelletizing.

Umthengi kufuneka abonelele ngecrane, iforklift okanye ezinye izixhobo zokuphakamisa, izinto zokuxhoma kunye nezixhobo.

Indawo: iza kuyilwa ngokoyilo lomgca.

1.2Ukunikezwa Amandla

Amandla afakiweyo:I-106KW (ukusetyenziswa kwamandla okusebenzayo kuya kuba malunga ne-70%)

Ukunikezwa Amandla:

Umbane wokubonelela: 3 * 380V + N + PE;

Ukunyamezela kwamandla ombane: + 10%/-5%;

Umbane wokulawula: 24VDC + 220VAC;

Ukuphindaphinda: 50Hz+-2%

Ucingo/iintambo:

-Iingcingo / iintambo ezisuka kumbane ukuya kulawulo lwekhabhinethi (zibonelelwa nguMthengi).

- Zonke iintambo zombane ukusuka kwikhabhinethi yolawulo ukuya kumatshini ngamnye (ubonelelwa nguMthengi).

1.3Ubonelelo ngamanzi

Ukusetyenziswa:0.6T/h (amanzi asetyenziswe ngokutsha)

Amanzi okupholisa:

Ngaphandle kweeminerali ezinyibilikisiweyo okanye ezimisiweyo njengephosphor, isulfure, intsimbi, njl.

Ubushushu bokungena T1: max.15℃

Ubushushu obuphumayo T2: T2=T1+5℃

Uxinzelelo lokungena, min: 2.5 imivalo

Ubunzima: 5-8ºdH;

I-Reflux: ngaphandle koxinzelelo

Umbhobho wamanzi:

Ukusuka kunikezelo lwamanzi ukuya kumatshini ngamnye (onikezelwe nguMthengi).

1.4Umoya oxinanisiweyo:0.6M3/min, 0.4~0.7Mpa

1.5Abasebenzi bokusebenza

2-3 Abantu

1.6Ioli yokuthambisa

Ifunyanwe kwimarike yendawo ngokwesindululo soMthengisi (ubonelelwa nguMthengi).

2. Imigaqo yorhwebo

2. 1Machine uluhlu & Ixabiso

| Hayi. | Igama Lesixhobo | Umzekelo | Ubuninzi(iseti) |

| 1 | Ukuhambisa ibhanti | | 1 |

| 2 | iCompactor | | 1 |

| 3 | DJ85/33 isikrufu esinye isikrufu | DJ85/33 | 1 |

| 4 | Uhlobo lwepleyiti yokutshintsha isikrini seHydraulic160 | | 1 |

| 5 | Inkqubo yokusika iringi yamanzi | | 1 |

| 6 | Umatshini wokukhupha amanzi kwiscreen esingcangcazelayo | | 1 |

| 7 | Silo | | 1 |

| 8 | Ikhabhinethi yombane | | 1 |

2.2 Imigaqo yentlawulo

- 40% njengediphozithi nguT/T.

- 60% njengebhalansi nge-T / T ngaphambi kokunikezelwa kunye nasemva kokuhlolwa.

2.3 Ixesha lonikezelo

Kwiintsuku zokusebenza ezingama-50 ukususela kumhla wokufumana idiphozithi.

2.4 Ukupakisha

Ifilimu yeplastiki.

2.5 Iwaranti

Iinyanga ezili-13 zezahlulo zoomatshini ukusuka kumhla wetyala lokulayishwa.Isiqinisekiso seenyanga ezintathu sezinto zombane ukuba umbane kwifektri yoMthengi awuzinzanga.

I-cuishi iya kuhlawulisa ixabiso lexabiso loMthengi lamacandelo asecaleni emva kokuba isixhobo siphume kwiwaranti kwaye ibonelele ngesikhokelo sobugcisa sexesha elide.

2.6 Ukufakela nokugunyaziswa

-Umthengi kufuneka alungiselele ukufakela xa isixhobo sifikile, njengombane, unikezelo lwamanzi, abasebenzi kunye neekhreyini, njl.

- i-cuishi iya kulungiselela isicelo se-visa yeenjineli, eziya kwifektri yoMthengi ngokugunyazisa umsebenzi.

-Umthengi kufuneka ahlawule amatikiti ohambo lokuya nokubuya kwiinjineli ukuba isicelo se-visa samkelwe, kunye neendleko eziveliswayo ezinje ngemithetho ye-visa, ukutya, indawo yokuhlala kunye nesibonelelo se-USD100 ngosuku kwinjineli nganye.

2.7 Ukunyaniseka

- Iintsuku ezingama-60 ukusuka kumhla wocaphulo.

3. Iinkcukacha zobugcisa

3.1DJ85 Isikrufu esinye

| 1 | Ukuhambisa ibhanti |

| | Njengoyilo olusemgangathweni, inkunkuma yeplastiki efana nefilimu, isilika, intambo, iingxowa, amalaphu angalukwanga athunyelwa kumgqomo wokudibanisa wenkqubo ye-cuishi ngokusebenzisa isixhobo sokutya ibhanti.Isantya sokuhambisa isixhobo sokutya kwebhanti sidityaniswe nokugcwala komgqomo wokudibanisa, kwaye isantya sokuhambisa inkunkuma sihlengahlengiswa ngokuzenzekelayo ngokugcwala komgqomo wokudityaniswa. Amandla eMotor: 1.5kw Ububanzi bomthumeli webhanti: 400mm Ubude bothutho: 5000mm Ngesixhobo sentsimbi: uphawu lwaseTshayina |

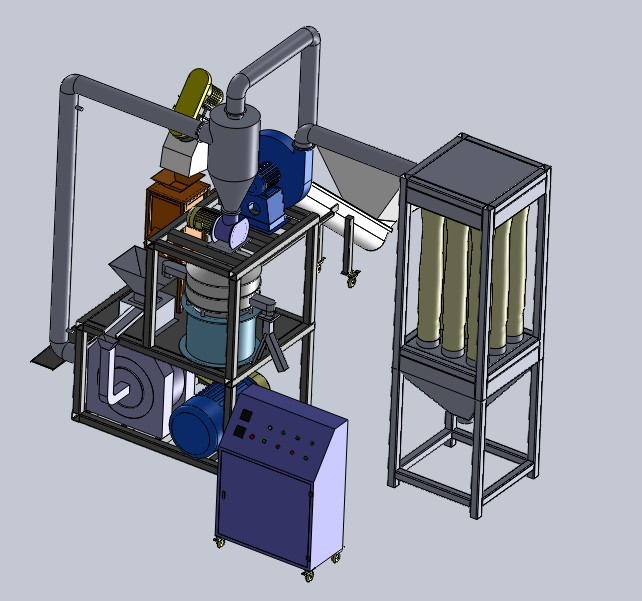

| 2 | iCompactor |

| | Imela eshukumayo kumgqomo wokudibanisa iyajikeleza ukusika nokutyumza inkunkuma engena emgqomeni.Imela ejikelezayo enesantya esiphezulu, ngelixa ityumza imathiriyeli, ivelisa ubushushu obuxubeneyo ukomisa kwangaphambili inkunkuma.Ngexesha elifanayo, ngoncedo lwenkqubo yokulawula ukushisa okwenzelwe ngokukodwa kunye nenkqubo yokulawula isantya, inkunkuma ebamba ukushisa iqhutywe ngaphambili ngaphantsi kweqondo lokushisa.shwabana.Inkunkuma yangaphambili idityaniswe ngumjelo wesikhokelo ngaphakathi kwindonga yesisele, kwaye inyanzeliswe kwi-extruder feed barrel ngamandla we-centrifugal wemela ejikelezayo.Ngale nkqubo edibeneyo yokutyumza, ukomisa kunye nokudibanisa, ukuzinza kunye nokusebenza okuphezulu kokutya inkunkuma kunye nobuninzi obuncinci buqinisekisiwe. Amandla emoto: 37kw Ulawulo lobushushu Indlela yokupholisa: ukupholisa amanzi Ubuninzi bamagqabi ajikelezayo: 4PCS Ubuninzi beencakuba ezilungisiweyo:9PCS Ukuthwala: NSK Amalungu aqhagamshelwe ngemathiriyeli yintsimbi engenasici |

| 3 | DJ85/33 I-screw extruder enye |

| | Icandelo lenkqubo ekhethekileyo (umgqomo, isikrufu) eyenzelwe iintlobo ezahlukeneyo zenkunkuma inokunyibilika kwaye ifake iplastiki imathiriyeli yenkunkuma egayiweyo ngobunono. Inkunkuma yeplastiki iya kunyibilika ngokupheleleyo kwaye yenziwe iplastiki ngaphakathi kwenkqubo yoyilo ekujoliswe kuyo ubude be-32D ukuya kwi-36D. Ibhokisi yegiya:i-torque ephezulu, ingxolo ephantsi, amazinyo aqinileyo okusila ibhokisi yegiya enomjikelezo wokupholisa wangaphandle Amandla eMotor: 55kw, Ukulawulwa rhoqo nge-inverter Isantya se-screw: 0 ~ 120rpm Izinto ze-screw kunye ne-barrel: 38CrMoA1A, unyango lwe-nitride Ubunzima bonyango lwangaphakathi: 0.4 ~ 0.7mm, IM/D: 33:1 Ububanzi be-screw: φ85mm Indlela yokupholisa: nyanzela indlela yokupholisa umoya Indlela yokufudumeza: ngezifudumezi Indawo yokufudumeza 6 Amandla okufudumeza malunga ne-48KW Indlela yokupholisa ifeni yokupholisa: 0.33KW X 5 = 1.65KW Inkqubo yokucoca i-vacuum kabini: Impompo yokufunxa: 2.2kw Isimbo sokuhluza: ukuhluzwa kwamanzi. Igumbi lokucoca: uyilo olukhethekileyo, imimandla ephindwe kabini. Vacuum ityhubhu: ubushushu kunye noxinzelelo iityhubhu zerabha. Ukukhupha okusebenzayo okuguquguqukayo okufana ne-micro-molecule kunye nokufuma ukusuka kwinyibilika ukuphucula umgangatho weegranules. Inkqubo yokuzikhusela: Ukukhuselwa komthwalo ogqithisileyo wemoto. Ukhuseleko loxinzelelo olugqithisileyo lwesikrufu. |

| 4 | Uhlobo lwepleyiti yokutshintsha isikrini seHydraulic160 |

| |  | Imilinganiselo (mm) | | d1 | d2 | d3 | d4 | h1 | h2 | D1 | D2 | D3 | N-M1 | N-M2 | L | W | H | | Φ280 | Φ254 | Φ254 | Φ280 | 6 | 6 | Φ380 | Φ330 | Φ266 | 12-M24 | 8-M20 | 420 | 230 | 480 | | Indawo yokucoca | Umthamo | Amandla okufudumeza | Amandla ombane | Uxinzelelo | Ubushushu | | 550cm² | ≤2200kg/h | 10.2kw | 3kw | ≤35MPa | ≤350℃ | |

| Ipleyiti enye yokutshintsha isikrini sesikhululo esiphindwe kabini: · Isifudumezi esimile okweringi ukwenzela ukufudumeza okungaguqukiyo kunye nokuzinzileyo. · Ukusebenza okungavuziyo kunye nokutshintsha kwesikrini ngokukhawuleza. · Isixhobo sokutywina esithambileyo. · Isikrini esingenasici: ukuchaneka okuphezulu, ukunxitywa kunye nokumelana noxinzelelo. Ububanzi: 160mm Amandla ombane we-hydraulic: 2.2kw |

| 5 | Inkqubo yokusika iringi yamanzi |

| |     |

| | 1. Isantya se-pelletizing blade sihlengahlengiswa ngokuzenzekelayo kuze kube yilapho kuvela iipelisi zokugqibela zeyunifomu.2.Isixhobo somoya sisetyenziselwa ukondla imela ukuqinisekisa ukudibana okuhle phakathi kwe iblade kunye nokufa, kunye noxinzelelo lwemela luhlengahlengiswa ngokuzenzekelayo qinisekisa amandla afanayo okusika imela. Qala inkqubo ngesitshixo esinye ukwenza ukusebenza kwenkqubo yonke ngakumbi luncedo; Umsiki wobuso othe tyaba Amandla okusika: 2.2kw Amandla epompo yamanzi: 2.2kw I-cutter lulawulo lwama-frequency nge-inverter |

| 6 | Umatshini wokukhupha amanzi kwiscreen esingcangcazelayo |

| Isikrini sokungcangcazela esikwinqanaba eliphambili elidityaniswe ne-horizontal centrifugal drying inokufikelela ekusebenzeni okugqwesileyo kokumisa kunye nokusetyenziswa kwamandla aphantsi.cuishi yamkela idizayini evaliweyo kwaye ixhotyiswe ngesigqubuthelo esingenasandi, esinengxolo ephantsi kwaye isebenziseka ngakumbi. Amandla emoto: 0.25kw*2. Iindawo ezidibana namanzi: SUS304. Hlanganisa iisefu: azifakwanga.Ifakwe kwaye ilungiswe ngezikrufu, ukwenzela ukuba kube lula ukubuyisela iisefu ezintsha kwixesha elizayo. Imithombo ijikelezwe ngerabha, ukuthintela umahluko omkhulu weamplitude obangelwa kukuguga kwentwasahlobo. Uyilo olukhethekileyo lokuthintela ukungcola okuncinci ukuwela kwimpompo yamanzi. Amandla emoto: 3kw. Isantya sokujikeleza: 1460rpm Amalungu adibana namanzi kunye neegranule: SUS304. |

| 7 | Silo |

| | Umthamo osebenzayo: I-700LMaterial yecandelo ekudibaneni nezinto zensimbi engenasici |

| 8 | Ikhabhinethi yombane |

| | Inkqubo yolawulo ithatha ulawulo lwe-Siemens, kwaye ixhotyiswe ngescreen sokusebenza somgangatho woshishino (ukhetho lokuzikhethela) - I-Smart on: Isitshixo esineqhosha elinye

Ngokutsho kolandelelwano olucwangcisiweyo olucwangcisiweyo kunye neemfuno zenkqubo yokuphatha izinto, inkqubo ye-cuishi edibeneyo iqonda ukuqaliswa kweqhosha elilodwa, ngaloo ndlela igwema iimpazamo kwinkqubo yokuqalisa. - Ukuvalwa kwe-Smart: ukuvala iqhosha elinye

Ngoncedo lweyunithi elungiselelwe ngokukhethekileyo, inkqubo ye-cuishi inokuqonda ukuvala iqhosha elilodwa lemodyuli yenkqubo yonke ukuze ugweme umonakalo wezixhobo ezibangelwa ukusebenza okungalunganga ngexesha lokuvalwa kwencwadi. - Isixhobo sokumisa ixesha likaxakeka

I-cuishi ixhotyiswe ngomsebenzi wokumisa ungxamiseko, osetyenziswa njengengxakeko kwimingcipheko engaqinisekanga ngexesha lokusebenza komatshini, ukuvala yonke inkqubo ngokukhawuleza kwaye ngokukhawuleza ukuphepha iingozi zesibini kunye nokulimala. Isixhobo sokukhusela ubomi Inkqubo ye-cuishi iqwalasela ngokupheleleyo imiba yokhuseleko lwezixhobo ngexesha lokusebenza.Isikhululo ngasinye sokusebenza kunye nesigxina senxalenye ejikelezayo sixhotyiswe ngokutshintshwa kokhuseleko lwe-elektroniki ukuqinisekisa ukhuseleko lwezixhobo ngexesha lokusebenza kwaye ugweme iingozi ezinokubakho ngexesha lokusebenza kwezixhobo zokubangela umonakalo kubaqhubi bomthengi. - Ukugcinwa kokusebenza kweplastiki

Ngoncedo lwenkqubo yokulawula ukushisa okuchanekileyo kunye noyilo olujoliswe kuyo lwecandelo le-plasticizing process, inkqubo ye-cuishi inokuqinisekisa ukuthembeka kunye nokuzinza komgangatho wokugqibela we-pelleting. - Isixhobo sokukhusela ukufudumeza kwigumbi lokudibanisa

Ngoncedo lomgaqo wolawulo lwemodyuli kunye nokuqonda ngokupheleleyo ukusebenza kwezixhobo ezahlukeneyo ezisetyenzisiweyo, inkqubo ye-cuishi inokuqinisekisa ukuba inkunkuma esetyenzisiweyo ifezekisa ubushushu obuphezulu kunye nemeko yokudibanisa kwigumbi lokudibanisa, kwaye inokuphepha izinto zokubuyiswa kweplastiki ekubeni zihlanganiswe. .Ukushisa ngokugqithiseleyo okanye ukuthotywa kwendawo yokugcina impahla. Umnxibelelanisi: Schneider Udluliselo: CHNT Ukutshintsha ngokubanzi: CHNT Umqhekezi wesekethe: CHNT Qaphela: Umthengi kufuneka anikeze ucingo oluvela kwikhabhinethi yolawulo kumatshini ngamnye.

|